A primer on spotting unprofitable jobs before they make it to a bay.

“Every time I walk into this place, you guys clean me out for a few grand.”

I’m sure you’ve heard some variant of that if you’ve written service. Part of the reason is that the value of preventative maintenance is just lost on some vehicle owners. (“Don’t try to upsell me…”) The upshot of this is they wind up only coming in when the car or truck is completely undriveable.

But there’s another reason lurking in the shadows.

Some customers avoid us like the dentist because they truly are surprised at that huge number at the bottom of the RO, and though it may seem like a not-so-scary estimate, it hasn’t been explained to them in terms of priority, and their response is to clam up and forget about it. So as a service writer, I developed what I called the “three-box” system. (This is wholly different than the four-square, for those of you who have sold cars at dealerships.) The system is simple, easy to remember, and builds confidence and repeat customers, and can help convert customers who pay for repair into ones who pay for preventative maintenance.

Here’s how it works. Every item on that estimate needs to be arranged into three boxes. Color coding with a few highlighters works well, too. Just make it something easily understood visually.

Whether you color code or use boxes or something else, taking the time to break down the car can be helpful. Much like when you forget all the stuff the doctor told you, taking time and not rushing can pay off big in the coming months. Photo by Lemmy.

Box One contains all your “this is why you came in” stuff. Basic safety items go here. Anything hazardous to human health is contained in Box One. Do not pass go, do not collect $200. Stuff that commonly shows up in Box One:

In seriousness, this is your basic pre-ride checklist. It’s real dangerous stuff that usually addresses the concern for the visit and/or things that are detrimental to safety of the vehicle or its occupants. Repair items usually go here. Maintenance usually does not.

Box Two is where I would normally put items that were something that needed to be addressed at the next regularly scheduled interval or maybe something that could slide for a little bit, especially if Box One had some heavy hitters. Here are some textbook Box Two items:

Now some of you are going to chastise me here, and that’s good! Judgment goes a long way here. A timing belt on a freewheelin’ engine that’s four thousand miles away from the service interval is obviously different than the cracked belt on an interference engine that’s 15k past due. Obviously if a diff has been spewing lube that’s potentially pressing, so you gotta use your noodle a little bit and either know what you’re looking at under the car or trust your techs to give you good intel. (You are getting underneath these cars, right?)

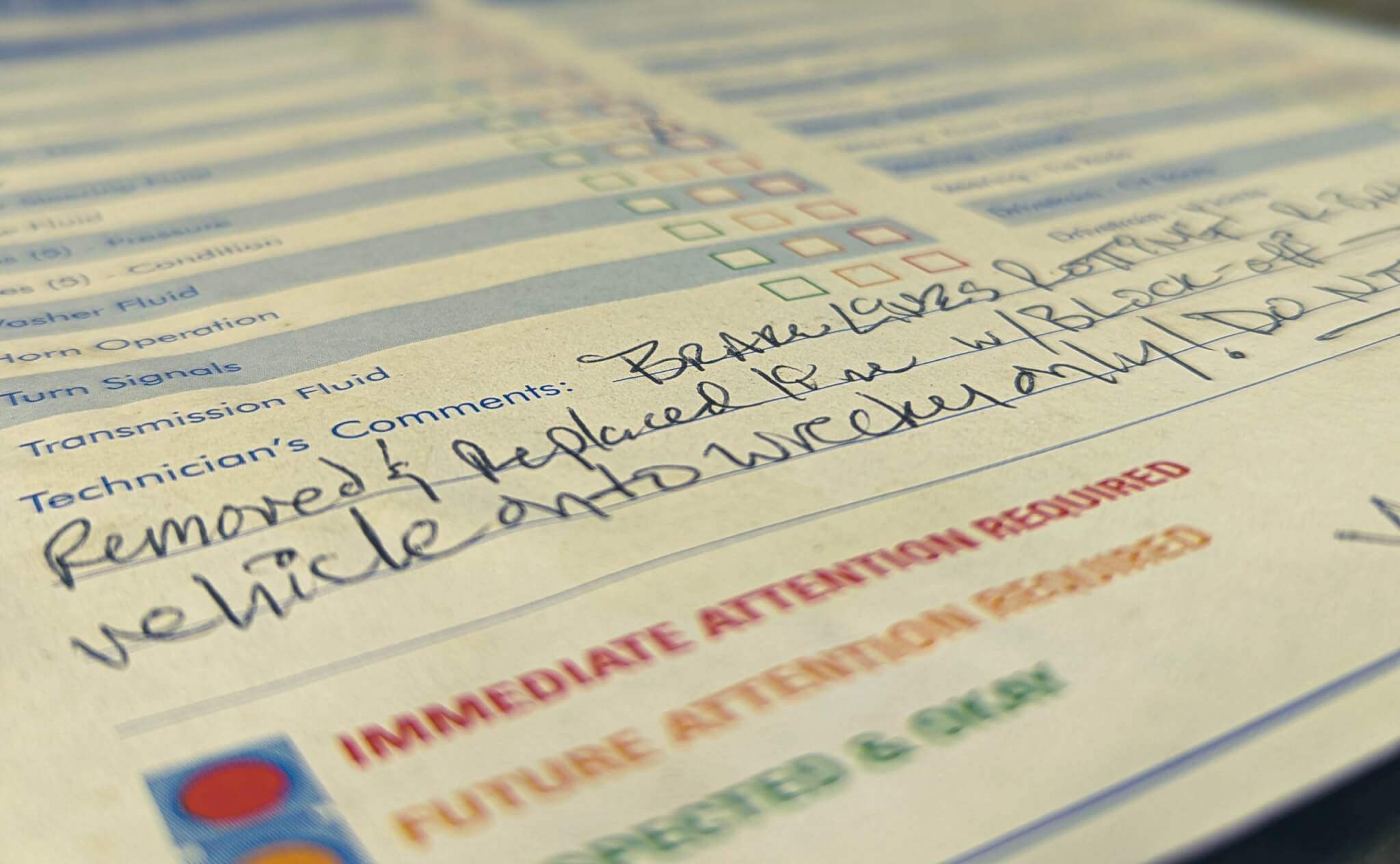

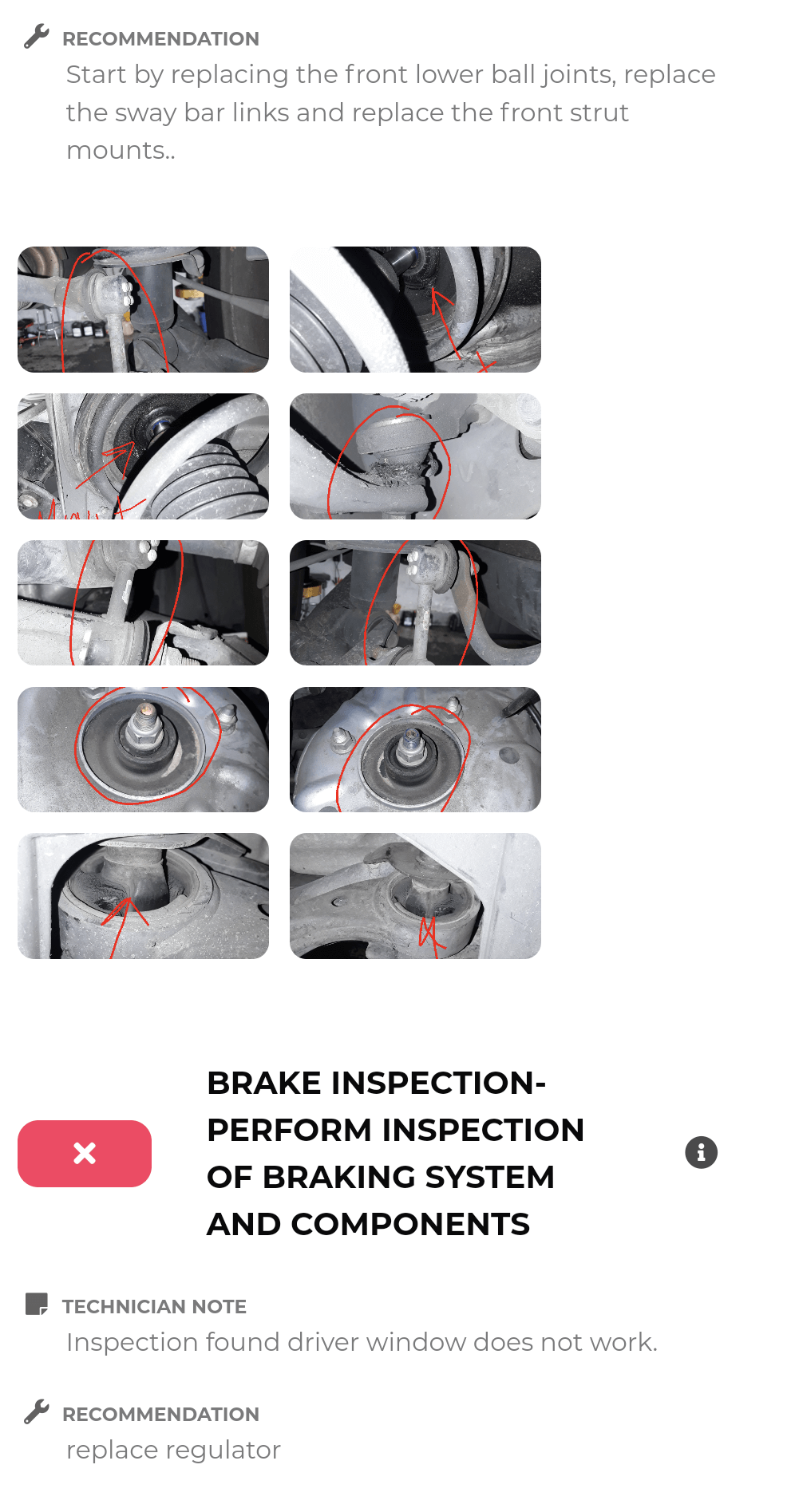

A customer sent me this estimate. I see a recommendation of replacing lower ball joints, stabilizer end links, and strut mounts, with an overwhelming amount of pictures. (How do you show a customer a photo of a bad ball joint?!) Next there’s a big red X regarding a brake inspection (yikes!) with no information, and then a note that the window reg needs to be replaced. While I don’t doubt all this work was needed, it’s not organized in an easy way for a customer to understand, nor does it appear prioritized particularly well.

Generally speaking, though, slightly scarier items can go here because the customer is going to have a little time to plan for the repair and some opportunity to get the money together if that’s a concern. (Plot spoiler: it always is.) This is an excellent time to point out that there is some time and thus some breathing room as these items are not as imminent as Box One stuff if you happen to notice your customer hyperventilating.

Box Three is where I would put highly discretionary purchases or ones that were not immediately pressing. Some of the common Box Three tenants included:

Most of these things are items customers want to work correctly, but they also don’t impact the business of getting from A-to-B. A customer can elect to repair them today, tomorrow, or maybe never.

I’d be a liar if I said there are no downfalls to this system. There are. The first is that this is not useful on every car that rolls in. If you’ve got a customer who’s coming in for scheduled preventative maintenance, good God, don’t use this estimate format! Similarly, it does no good to write an estimate on a real hooptie with this—you’ll quickly convince a customer to just dump the car and move on to another one.

Now with all that having been said, when I got to a new shop and started selling service like this, I’d starve for a little bit—immediate work was often the bulk of what I was selling. After a few months, though, jobs would start rolling in. Customers would call to schedule that strut job. (That was also nice because I could have the parts waiting on the car.) And you know what? Sometimes when I had a light week, a few timing belts or cat-back exhausts I’d written months earlier would start showing up on the schedule, and the nice, predictable bills made for some calm customers. Seeing me started being less painful, all thanks to three little boxes.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.

Modern vehicles equipped with Advanced Driver Assistance Systems (ADAS) are truly marvels of engineering. What started...

In Part 1 of this piece, we looked at Sergio Pininfarina’s career up to 1987. In this part, we’ll take a look at his...

Service writers, this piece is aimed squarely at you. You may be aware of many of the costs of doing business....