“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

You know topping off brake fluid is generally a no-no, but when a customer’s brake fluid needs to be flushed completely, knowing what to put in the reservoir isn’t as clear-cut as it once was. The master cylinder cap may say the vehicle uses DOT 4 brake fluid, but are you aware there are different types of DOT 4 fluid? The one you choose is more important than ever because of a modern addition to brakes: autonomous braking.

Vehicles protect motorists in a few ways that are generally grouped under the umbrella term “ADAS.” (Advanced Driver Assist Systems) These include everything from ABS and traction control to today’s autonomous systems like collision avoidance and automatic emergency braking.

Nearly all these systems rely on the proper operation of the foundational braking system to function. The foundational braking system consists of the conventional hydraulically operated disc and/or drum brakes. The addition of computer-controlled actuators, both hydraulic and electronic, allow these systems to react and initiate corrective action at speeds beyond what a human operator can achieve. These systems reduce the number and severity of accidents.

When an emergency braking situation occurs, the human element of reaction time is the first obstacle. Critical time also passes while a brake system attains maximum pressure—about 600 milliseconds (about ½ second) in a conventional system. Today’s autonomous braking systems (that is, any of the dozen or so in use that rely on the foundational brake system) reduce or remove human reaction time from the equation and build full pressure in a little more than 100 milliseconds.

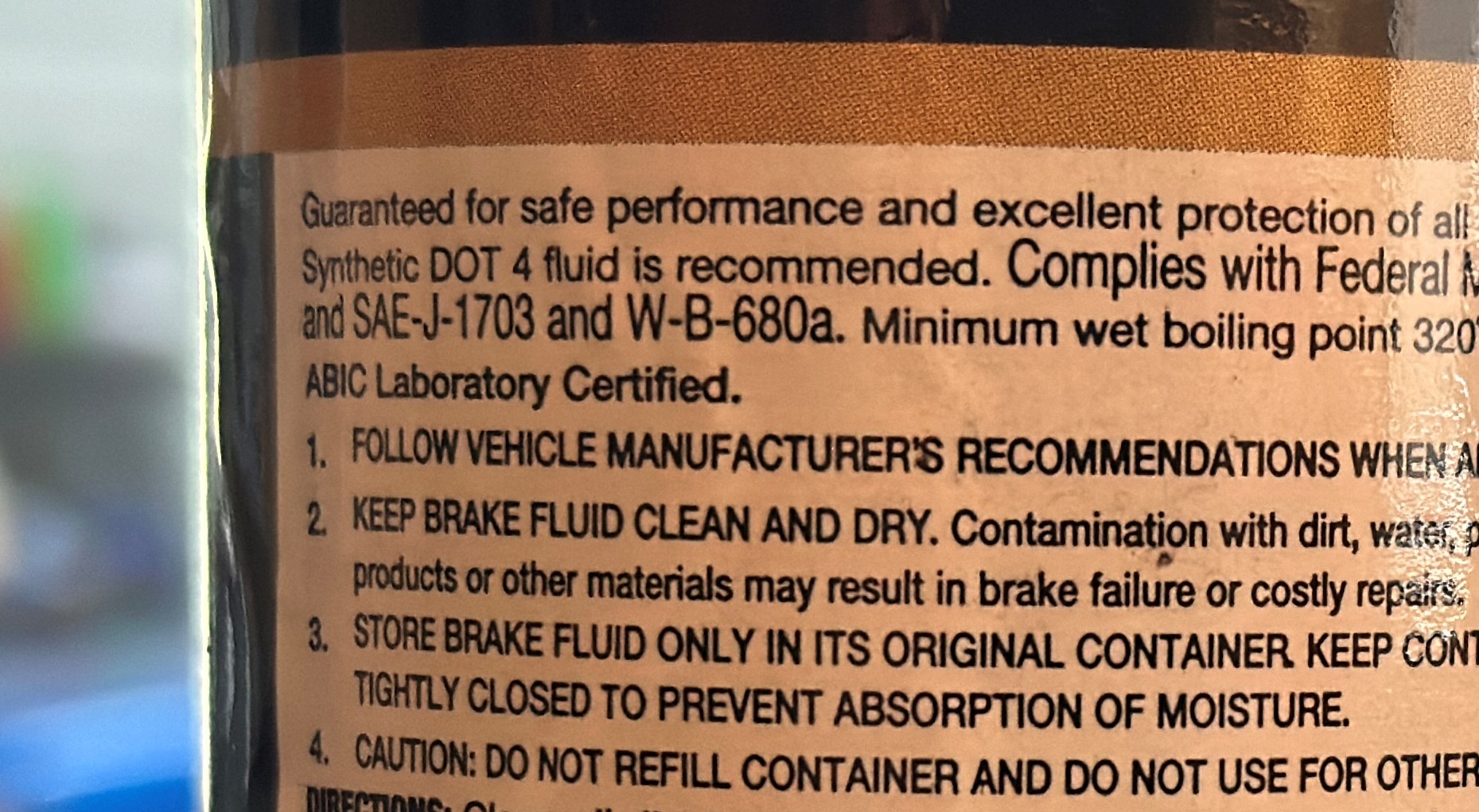

Since the early 2000’s, manufacturers moved away from DOT (Department of Transportation) 3 brake fluids to DOT 4. Fluid classifications are all covered under Federal Motor Vehicle Safety Standards (FMVSS). Besides specifying minimum certification standards for each, FMVSS section 571.116 effectively mandates that all automobile manufacturers identify any vehicle that requires anything beyond DOT 3 as requiring DOT 4.

Fluid manufacturers are required to label their brake fluids as DOT 3, DOT 4, DOT 5, or DOT 5.1. Any fluid rated DOT 5 or 5.1 requires additional warning statements under the standard.

But the FMVSS is only one standard brake fluids are certified to.

DOT 4 that meets this minimum standard has not been appropriate for any car labelled for DOT 4 for at least 10 years. Most vehicles in service today require a brake fluid with a lower viscosity, (measured in centistokes) than what the FMVSS alone require. To add to the confusion, SAE (Society of Automotive Engineers) and ISO (International Standards Organization) all have their own requirements for what we might think of as DOT 3, 4, 5, or 5.1 fluids. Each body has different standards for things like oxidation, corrosion, water tolerance, chemical stability, material compatibility, and stroking properties. Viscosity and boiling points are the biggest and most important differences you need to be aware of.

SAE has split their DOT 4 standards into separate standard viscosity and low viscosity categories under SAE J1703 and J1704 specifications. The ISO uses four separate categories (Class 4, 5-1, 6 and 7) for DOT 4 fluid. Class 6 and 7 have the lowest viscosity and allows the emergency braking systems the fastest response times. These are required by most manufacturers, but you likely won’t see the corresponding ISO specification or the manufacturer’s own specification on the master cylinder reservoir’s cap. All you’ll see is the DOT 4 requirement.

Before ISO Class 6 was introduced, one widely distributed technical research paper informally referred to the new (then) reduced viscosity fluids as “super fluids.” Even today, you’ll easily find brake fluids labeled as DOT 4+, DOT 4 Plus, or Super DOT 4. But there is no enforceable standard for any of these claims and most meet the older DOT 4 standards for viscosity. Unless they specifically list an ISO Class 6 or 7 certification, they may well be incorrect for a system requiring low viscosity fluid.

Photo: Peter Meier.

When servicing brakes, you must reference the service requirements for the system you are working on by looking it up in your professional service information source or by contacting the local dealer.

Finding the right fluid isn’t always easy. You’ll likely be better off ordering what you need in advance, or perhaps stocking it in your facility. But failure to use the correct fluid for a given vehicle will degrade the performance of all the vehicle’s ADAS that depend on near-instantaneous computer-controlled operation of the foundational brake system.

As a professional technician, I encourage you to do the job correctly. Research the service information for each vehicle and use the right fluid for the vehicle application—your customers are counting on you.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.