“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

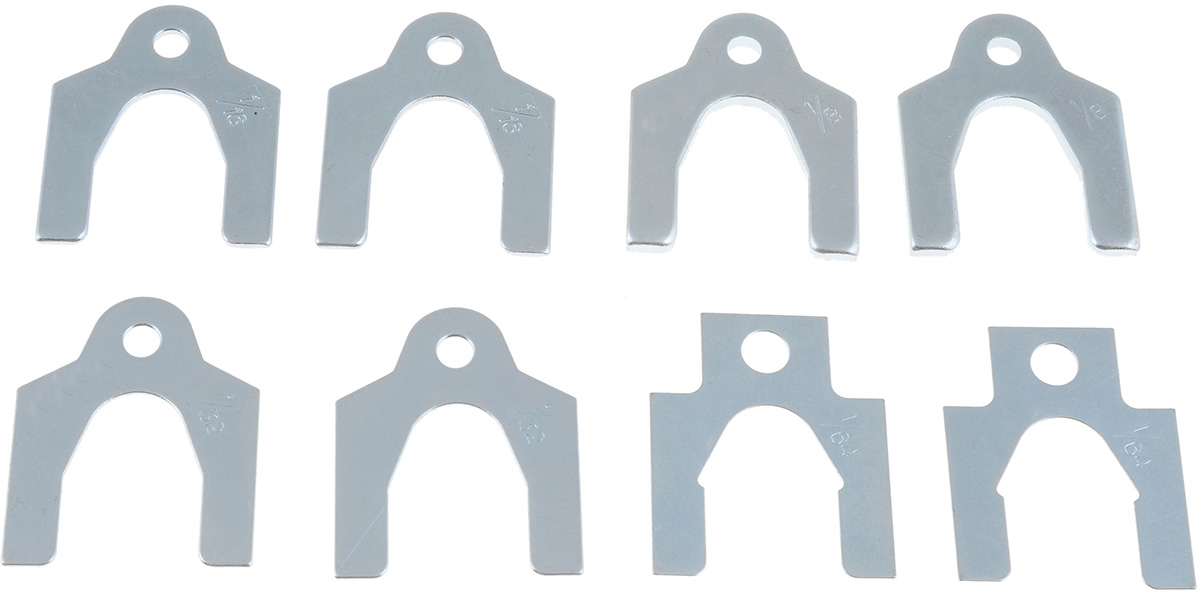

When you saw the image at the top of this article, you probably knew what you were looking at. If you hang panels all day, you said, “A body shim!” If your life is spent undercar, you said, “An alignment shim!” You might also think they’re for antiques. But shims have a few more uses around an automotive shop. Here’s some of the times I’ve reached for mine.

Yes, yes; everyone knows shims can be used to rectify weird panel gaps. (And starter shims can be used on the starter! Revolutionary!) But seriously, there are lots of lesser-known uses for these on a vehicle body that some of us on the mechanical side of the house don’t think about. I’ve used these to true up door hinges that just had poor fit from the factory. I’ve used them to compensate for not-quite-right bumpers that looked as though they were sagging. Latches are another area where some shim stock is just what the doctor ordered.

Sometimes when I’m laying something out that needs to be welded, a few shims are often all it takes to get something just where I need it so I can tack it up.

Every shop has machinery that needs to be level. Whether it’s the legs on the lathe or a mill, the standup compressor that’s bolted to the floor, or a drill press vise that doesn’t sit square to the table on which it is mounted, shims save the day. Heck… you probably have a huge version of these under your lift to keep that plumb!

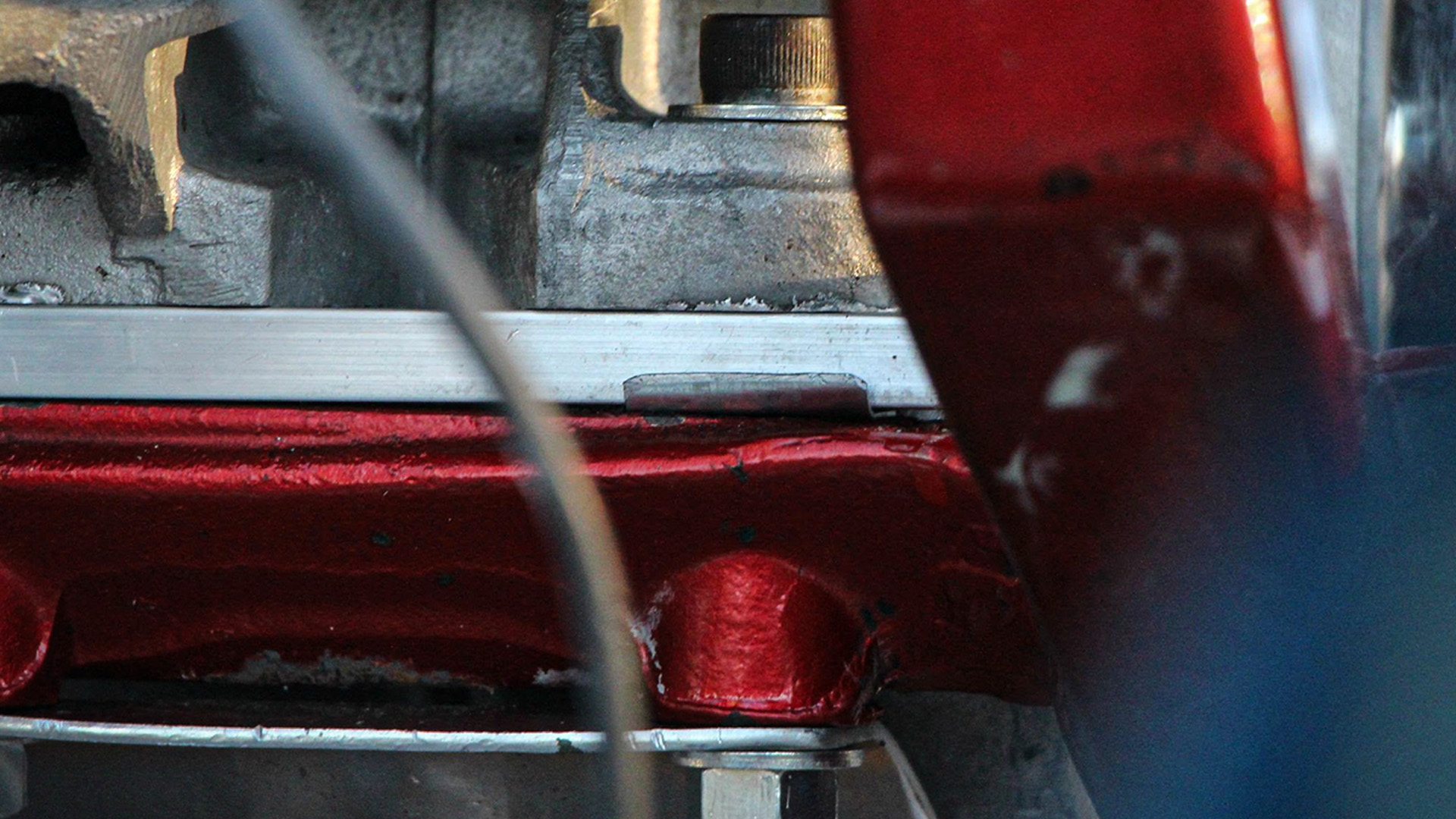

A shim in its natural environment, making this bumper appear level to the casual observer. Photo: Lemmy.

Whether a drive pulley is sitting off the drive belt’s plane or you’re working with a fan spacer that’s crushed, wonky, or drilled wrong, a shim can be just the ticket, especially if a face cut on a lathe isn’t possible.

Specifically, I use shims when mounting solid-mount Harley-Davidson engines into their frames. The soft aluminum of the engine cases can get hammered from vibration and between sloppy welds and accidents, the frames are often out of square. Special shout-out to our GM starter shims, which have both a hole end and a forked one—the forked end works great on the engine, and the hole is perfect for truing up the trans-to-trans-plate interface.

A GM starter shim has been used to level this Harley-Davidson engine, permitting the spacer beneath to sit flush to a frame casting that isn’t quite level. Photo: Lemmy.

If you want a fastener to sit in a particular orientation (for the visual aspect) but the torque would be incorrect, a shim might be the item to reach for. A shim with a closed end can also be trimmed to sit neatly under the head of a fastener so it’s “invisible,” too—think of it as acting along the lines of a very thin washer.

If you’re changing ride height of a vehicle (lowering or lifting), driveline angle often gets wonky, too. One can use shims under the transmission mount or leaf spring perches in the appropriate spot to help bring the angles closer to original geometry.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.