“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

Performing a visual inspection of a car part is usually the first step in assessing its condition. In the case of the serpentine belt, any sign of physical damage to the belt means the belt should be replaced, and may indicate the need to more closely inspect the driven components, tensioner, and belt pulleys.

But relying on a visual inspection of your customer’s serpentine belt alone is a mistake.

Since the late ’90s, serpentine belts have been made with ethylene propylene diene terpolymer, or EPDM. This synthetic material does not show visual wear until it is long past its useful life. Instead, you need to think of belt inspections more like a tire inspection.

Therefore, when inspecting a belt, gauge the wear of the ribs and grooves of the belt much like you check the tread depth of a tire. Do this with a special tool like the one shown below.

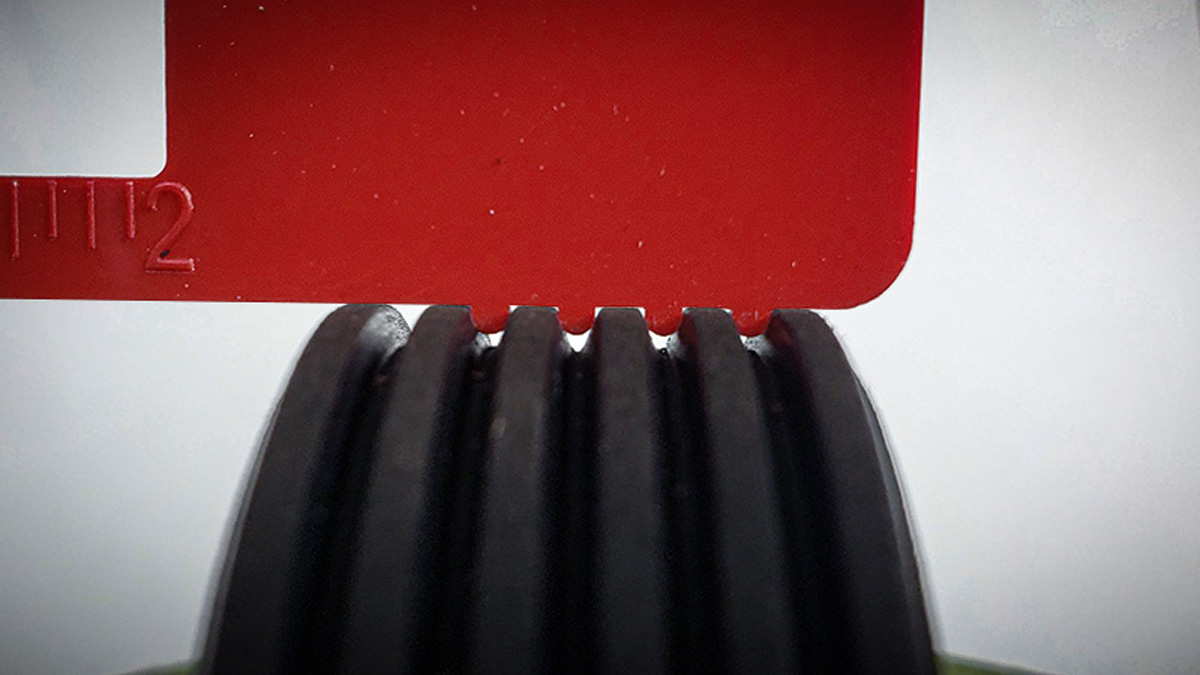

Many belt gauges use a series of teeth placed in the belt’s grooves to determine wear. Photo: Peter Meier.

Every belt manufacturer makes one, so appearance and use of the tools differ slightly. And every parts supplier usually has boxes of them in stock, available free to anyone that asks for one.

The most common gauge uses a series of teeth that can be rounded or come to a point. Use the tool by placing the tool perpendicular to the belt’s ribs, inserting the teeth into the belt’s grooves. If the tool lies flat on top of the belt ribs, the belt is worn and needs to be replaced.

However, using this style tool, if there is a gap between the top of the belt ribs and the tool, the belt can be placed back into service.

If a tool of this design lies flat on top of the belt ribs, the belt is worn past its service limits. Photo: Mike Apice.

If there is a gap between the base of the tool and the top of the ribs, the belt is still serviceable. Photo Mike Apice.

Some tools work by inserting teeth into the groove and inspecting the amount of free play between the tool and the grooves. Another tool, like the one shown below, is placed between adjacent grooves and moved radially, magnifying wear your naked eye might not catch.

The accessory belt drive relies on a wedging effect to effectively transfer power from the engine to the driven accessories. A worn belt can slip (yet may not cause the characteristic squeal you have heard before) and run hotter than it should. That means more heat is passed on to the bearings of the idler and tensioner assemblies as well as the alternator, power steering pump, air conditioning compressor, and in some applications, the water pump. That excess heat also means premature—and potentially costly—failure of these components. And remember, the belt tensioner is also a wear item. Replace it whenever you replace a worn belt to ensure maximum efficiency from the engine’s accessory drive. Failure to treat these components as a set could result in belt noise and a customer comeback.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.