“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

Hello. My name is Lemmy, and I am guilty of throwing away brake rotor screws.

At least I was guilty. I no longer commit this sin. You know the pieces I’m talking about. They’re the little screws with the huge heads that get boogered up when you try to remove them without an impact screwdriver, and then you get super-frustrated and drill them out enough that you can use the rotor to yank the heads off ‘em and then fight with the threaded stub that remains.

And if you’re like I am, early in your career you were putting a set back in or trying to find replacements, and some grumpy old tech said, “You ain’t gotta worry about those, kid. They just use them on the assembly line so the rotors don’t flop around while they’re puttin’ the wheels on.”

Wrong. I’ve rambled a bit about some brake job tips in the past, and I think this one is important enough to mention as a separate tip.

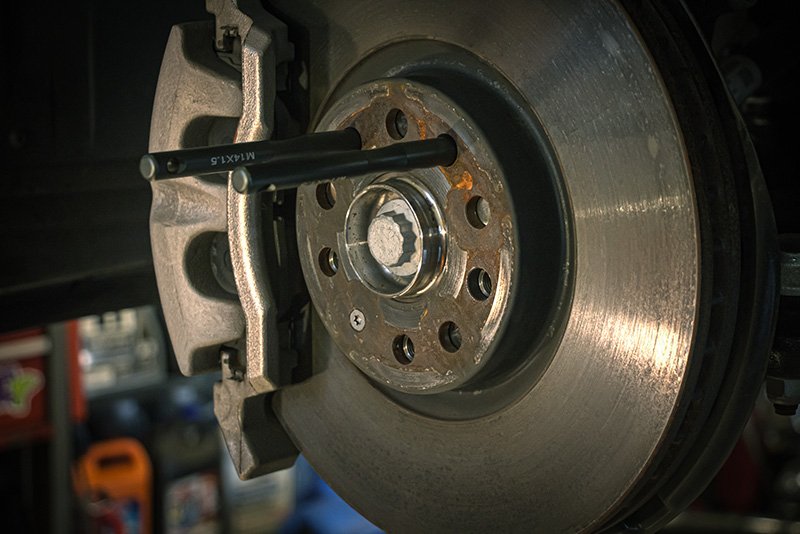

Without the screw in place, lining up wheel, rotor, and hub is quite the chore—especially if you don’t have a set of Dorman wheel hangers shown here. Photo: Lemmy.

If you’ve ever worked on a car with lug bolts, not studs, it’s immediately apparent why the rotor retaining screws are needed. Most German vehicles and a number of Fiat and Chrysler vehicles spring to mind. Conventional setups have female rotors, female hubs that are stuffed with a male stud, and female wheels. Since the hub on German cars is female, the rotor is female, and the wheel is female, an installer has to rotate all three of those items to get a wheel bolt in place.

Most of the time this involves both hands and a knee in a position I’ve heard referred to as “the Captain Morgan.” Of course, aftermarket “wheel bullet” tools render these unnecessary, but the factory-designed locating screws are pretty critical if you don’t have one of those tools. And even if you do—will your customer have one within reach when changing a flat on the side of the road? Make sure those screws are in place on these vehicles.

And all the rest of the cars? Well, if you take a look at the vast majority of the rotors fitted to them, you’ll notice most have a spot in the rotor that’s countersunk. And the reason for that is it allows one itty-bitty fastener to correctly locate the brake rotor.

“But Lem! The lug nuts will center it up!” I can hear you thinking right now. And that is true in the case of the wheel. The brake disc, however, almost always pilots off the hub.

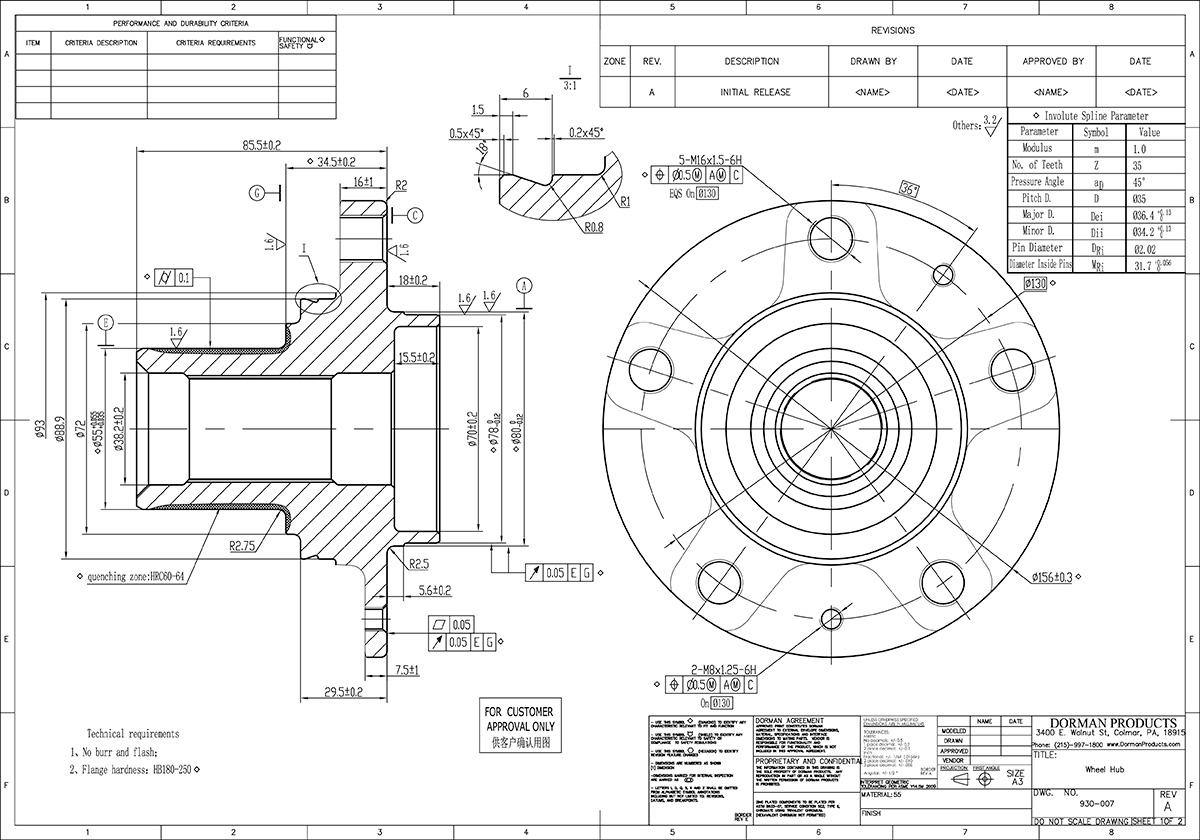

Simon Marenda, one of Dorman’s engineers who deals an awful lot with hub assemblies, educated me further. “Rotors are usually going to be hub-piloted. The lugs can have wider tolerances so the rotor will fit over them easily before having to climb over the hub flange when you’re installing them.” He then shipped me a drawing that confirmed this: there’s a step visible, plain as day.

See the double diameter in the drawing? That makes the initial installation easy, but then helps pilot the disc.

Of course, I would be remiss if I didn’t mention that my favorite auto parts supplier also happens to sell a healthy variety of these screws and many of your favorite distributors keep quite a few of these in stock since they fly off that same shelf at a pretty good clip.

I’m sure you’re replacing rotors and using top-notch friction materials and removing corrosion from all the surfaces. I also bet you’re not the type to skip lubricating slide pins and even recommend brake fluid flushes as part of a complete brake job. Why not add the rotor retaining screws?

After all, it turns out they’re on there for a reason!

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.