“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

Picture this: You’re installing a cylinder head, you’re tightening a head bolt to spec, and you’re feeling good—until crack! The sound every wrench-turner dreads hearing: your engine block saying goodbye to its structural integrity.

So, what happened? Chances are, a little fluid in the wrong place caused a big problem.

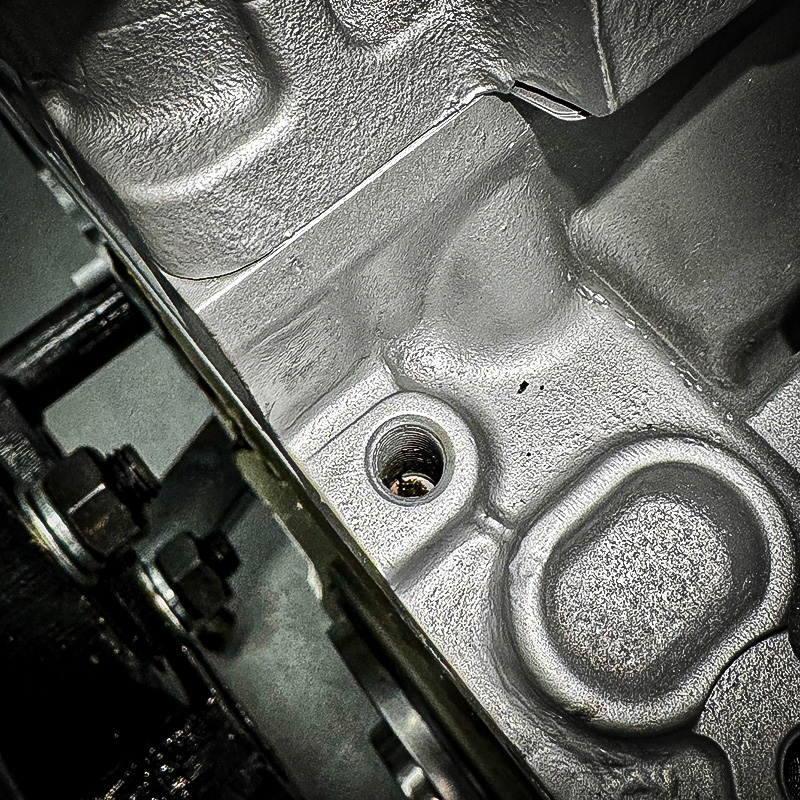

When coolant, oil, or leftover cleaning solvent sneaks into a blind bolt hole, it doesn’t just evaporate or disappear. As you tighten the bolt, that trapped fluid has nowhere to go, turning the bolt into a tiny hydraulic press and causing a massive pressure pocket. This unexpected pressure can cause an aluminum recipient of this bolt to push out the threads—or worse—crack.

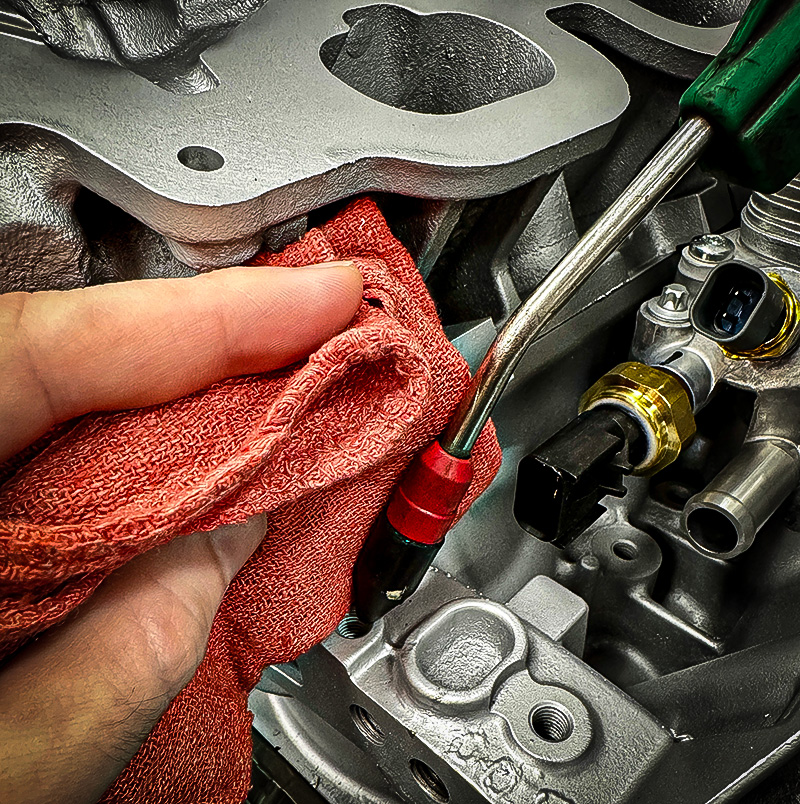

A cracked cylinder head or engine block can mean major repairs, big bills, and a whole lot of frustration. And the worst part? It’s easily preventable. Cleaning out those bolt holes isn’t just good practice—it’s essential for ensuring the bolt can get to its full depth, unimpeded, and safely reach its required torque spec, leaving everyone happy and a job well done.

Things to consider before reassembly around non-passthrough (blind) bolt holes:

And remember, if you’re working on an engine that’s had an oil or coolant leak, be especially diligent. Fluids love to hide in those deep recesses. A few minutes of cleaning can prevent catastrophic damage. It’s one of those small steps that makes a big difference.

Do you have a preferred cleaning method, or have you fallen victim to cracking an aluminum part with trapped fluid? Share your story with us!

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.