“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

As a little mechaniclet, I didn’t really give much thought to my air tool fittings or their air lines. Yes, the type of tool, the amount of air moving through the lines, and the distance from the compressor are all variables that determine how well a tool might work, but I was just too dumb to know those things. One thing I did know, though, was when I blew up a fitting I needed to ask for “L” style replacements.

As it turns out, that “L” is a grouping Milton industries gave to the style of fitting competitor Lincoln used. Those “L” fittings were common to every shop in which I ever turned a wrench, and that was smack-dab in the middle of flyover country in the Midwest. In time, I learned that style was common to that area, since all of my mechanical friends used that same style at their shops. And here is where I am going to ask for your help: I’d like to know where you are and what your shop uses. Here’s why.

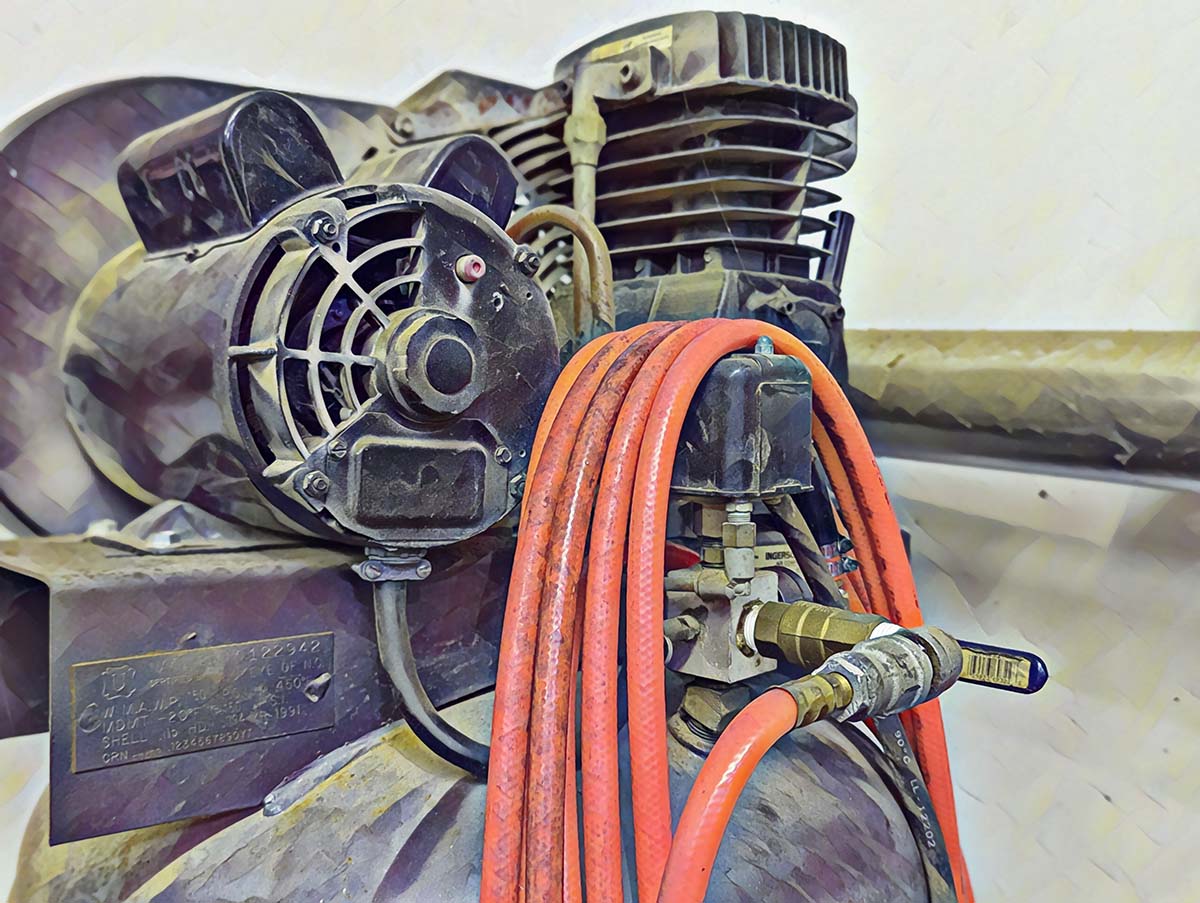

There iss quite a bit of variation in fittings used across the United States. Image by Josh Seasholtz.

The first time I tried to hook up tools here on the East Coast, I realized my fittings and couplers were all wrong. In the Keystone State, most places use what Milton calls an “M” fitting, which are also called “industrial.” I actually like these much better, because the “L” fittings have a long, narrow tail that breaks when mishandled. Once I switched to the “M” style, I stopped going through so many fittings on my tools.

Industrial-style fittings are common in many shops. What do you use? Image by Josh Seasholtz.I learned later that “D” and “G” styles are popular on the West Coast. In researching this article, I also found “Nitto Kohki” fittings are ubiquitous in Japan, Australia, and New Zealand. Luke, a Dorman technician in our Proving Grounds with a bit of heavy truck experience, tells me Tru-Flate-style (“T”) fittings are common in truck shops. According to Tru-Flate, this style has a wide surface that leads to better sealing and longer seal life, and also has lower pressure drops and greater air flow, which would make sense in a truck setting where torque specs are higher.

Industrial-style fittings are common in many shops. What do you use? Image by Josh Seasholtz.I learned later that “D” and “G” styles are popular on the West Coast. In researching this article, I also found “Nitto Kohki” fittings are ubiquitous in Japan, Australia, and New Zealand. Luke, a Dorman technician in our Proving Grounds with a bit of heavy truck experience, tells me Tru-Flate-style (“T”) fittings are common in truck shops. According to Tru-Flate, this style has a wide surface that leads to better sealing and longer seal life, and also has lower pressure drops and greater air flow, which would make sense in a truck setting where torque specs are higher.

To put another fly in the ointment, it seems as though many garage nuts feel the Milton “V” style checks a lot of automotive boxes in terms of flow, so those appear to be cropping up in many places without a unifying regional background.

Some shops run different fittings on different lines to prevent accidental hookups, like running a paint gun on a line with a tool oiler. Image by Josh Seasholtz.

And now, back to my original request: I’d like to know where you are and what you use, because our Creative Design Manager has agreed to make a map based on that input. I think it might be handy to know what fittings are in use in what parts of the country, and my hope is with enough feedback, we can make a fairly accurate map that’s helpful for any of us traveling to do some work.

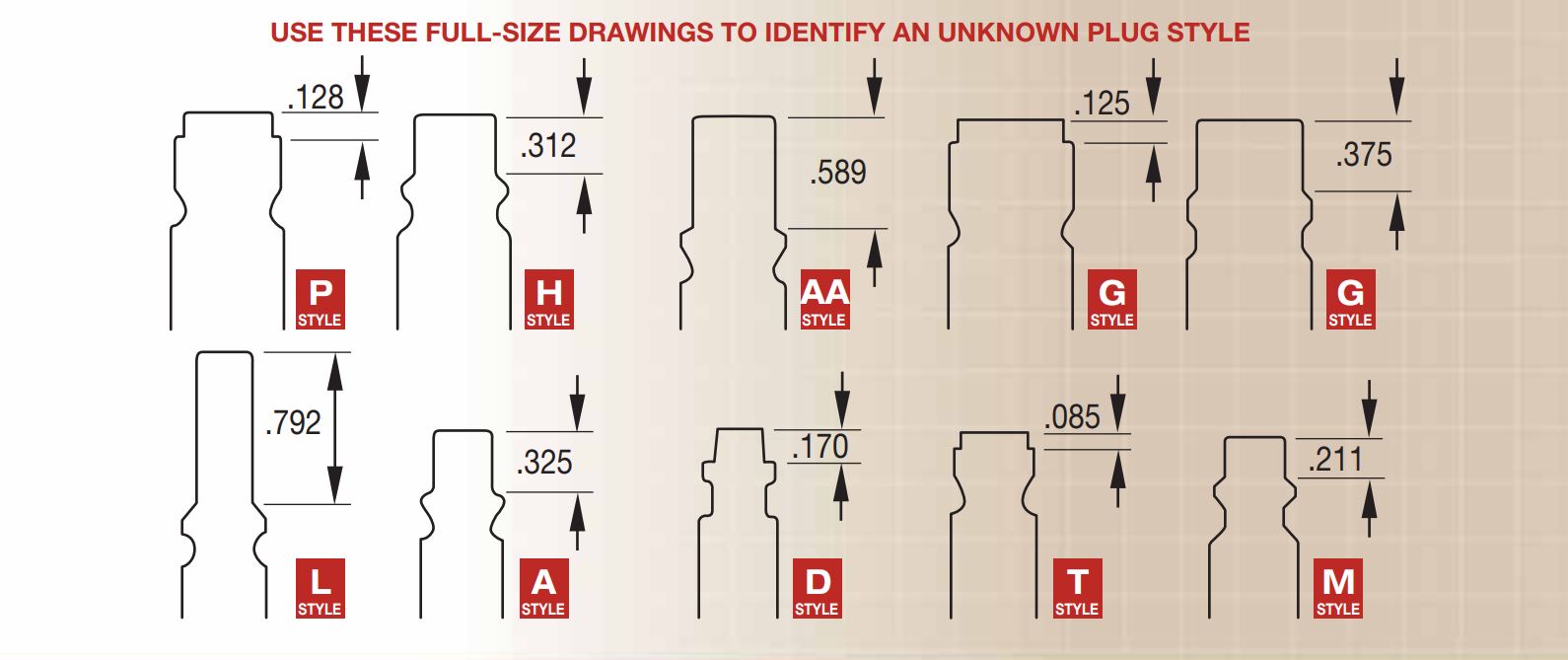

You can use the handy chart to determine what style you use if you’re not sure/. (It’s also a big help for figuring out what you need to adapt to.) It really only works on the fitting side; the couplers all look similar. Milton Industries image.

So thank you in advance! Just let us know where you are and what you use (and any other places you might know about from your travels) and we’ll record the data points and drop the map in here when we have enough collected.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.