“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

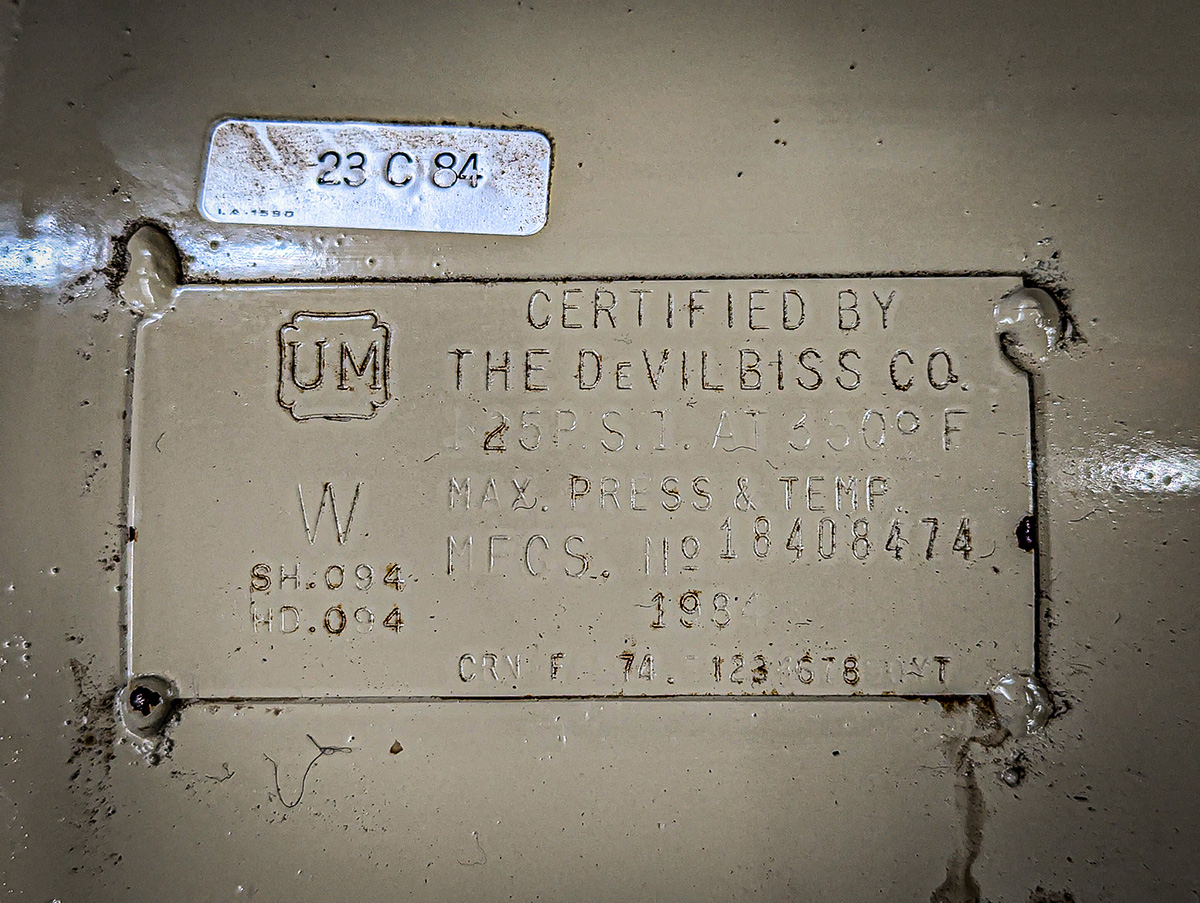

Here’s an underside photo of a one-horse air compressor that came with my home shop. I used and drained it regularly, but I don’t think the previous owner did. One day, a hissing noise let me know that something was wrong. You can see the pinhole leak in the photo. Photo: Andy Greaser.

If you’re new to auto repair, you might be wondering why air compressors need to be drained in the first place. Aren’t they just full of plain old air? Well, condensation can collect at the bottom of the tank, which in most cases, has an uncoated steel interior. And water plus bare steel equals rust. (Compressor tanks with rust-resistant liners are out there, but they cost a pretty penny.) Rust equals weak spots, which is bad news for a pressurized vessel.

The tank could not be salvaged, so I disassembled the compressor and chopped the bottom out to see how bad it really was. The results speak for themselves. Your shop’s compressor will be much larger and more powerful than this. Just sayin’…. Photo: Andy Greaser.

A little surface rust inside is no big deal. Advanced rust, on the other hand, causes pitting and degradation of the tank itself. Pinhole leaks are often the first signs of failure … if you’re lucky. Larger rusted areas can fail quickly and catastrophically. You’ve probably seen a few compressor tank explosion videos on YouTube by now, and if that isn’t enough motivation to keep up with emptying the tank, then what is? Consider the health of your air tools, as well, if your shop uses them. They’re air tools, not water tools! You likely have inline devices to scrub moisture out of the air supply before it hits the business end, and it is prudent to minimize that moisture before it ever leaves the tank.

All air compressor tanks are required by law to have markings with key information, including the date of manufacture. This tank was made in 1984, and the years have not been kind to it. Photo: Andy Greaser.

If you’re having trouble keeping up with regular drains, and scheduled maintenance (draintenance?) isn’t working, try making the process easier. Add a drain valve extension to avoid crawling around on the floor, fumbling around under the tank for the valve. You could also add an automatic drain valve without spending a whole lot of time or money, which can be especially handy for a compressor stored in a location that’s hard to access.

Finally, make sure everyone in your shop knows who is supposed to keep up with compressor maintenance. And if that person leaves to work at another shop, designate someone else! This simple job is too safety-critical to ignore.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.