“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

As a young mechaniclet, I fought springs often. Specifically, helical tension springs gave me metaphorical headaches and literal skinned knuckles. I encountered them most often when performing brake jobs on vehicles with drum brakes. I went through a ton of tools, then I got wise and made and bought a variety of spring hooks. I’ll explain what those are just after I walk you down my path of failed tools (which might just look like your own).

I first bought a Lisle 44800, and sometimes that wouldn’t get into the tight corners on some shoes. Worse, it could chew up and bend the little dainty springs often seen on toothed-wheel-style e-brake adjusters—if it was even helpful in those cramped quarters at all.

After that, I tried those big brake spring plier things we’ve all seen, but I’ve never been very good with them. First, they are huge, and a fine-motor skill spring install has to be done with larger muscles of the hands and arms. I always got frustrated with the tool and the process required to use it. Second, the twist-y end of that tool really winds up those springs. Finally, I don’t love pushing off the friction surface of the shoe to reinstall the springs if I don’t have to.

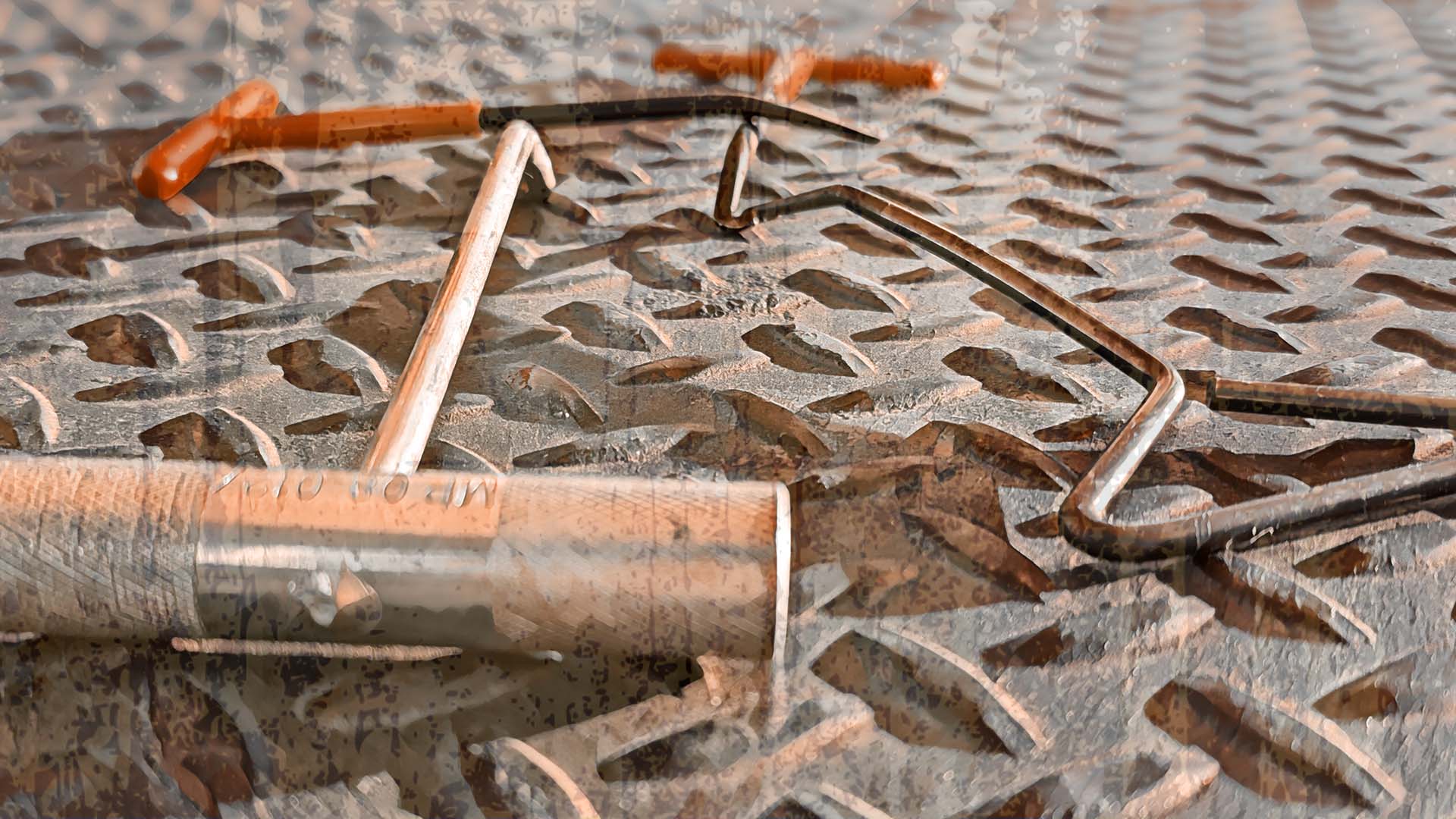

A few different end styles handle a surprising array of spring installation and removal scenarios. Photo by Lemmy.

If you have riveted shoes, the tool doesn’t hurt anything since ya can push off the rivets, but I haven’t seen a set of riveted shoes from the auto parts store in a long time. The absolute worst part to me is you need both hands, so if you have the spring’s hook close to where it needs to go but not quite there, you need a third hand to nudge it into place with a flathead screwdriver or something similar.

So then I tried pliers, but they don’t work well on heavier springs, although they are effective for the little e-brake springs I was messing up with my threaded Lisle tool. (Incidentally, the flat nose of my lineman’s pliers has also proven over the years to be pretty good for getting hold down springs into place.)

One of my ideas came to me in a fit of frustration when fighting a spring during a brake job. Exhaust sections on motorcycles, ATVs, UTVs, and sleds are held together by pairs of hooked tension springs. Every motorcycle mechanic has one or a dozen tools for dealing with those. I walked to my box, grabbed mine, and put the spring in place faster than it took to read this paragraph.

Inexpensive to buy or easy to build, and handy in some tight spots. Image by Josh Seasholtz.

They are, to me, the perfect blend of finesse and muscle for the job of installing automotive drum brake springs. (I know, I know, nobody works on drum brakes these days.) Spring hooks are much smaller than the big plier things, and if you’ve got one of these, you can usually get by without any of the other specialty tools (especially if you can figure out something for the hold down springs as I mentioned earlier). They are very inexpensive to buy and nearly free to make, and my favorite part is how useful they are in some other spots. I have also used mine on:

…and of course, eight jillion slip-on mufflers for powersports-related toys.

They’re cheap and useful. I highly recommend adding one to your box.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.