“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

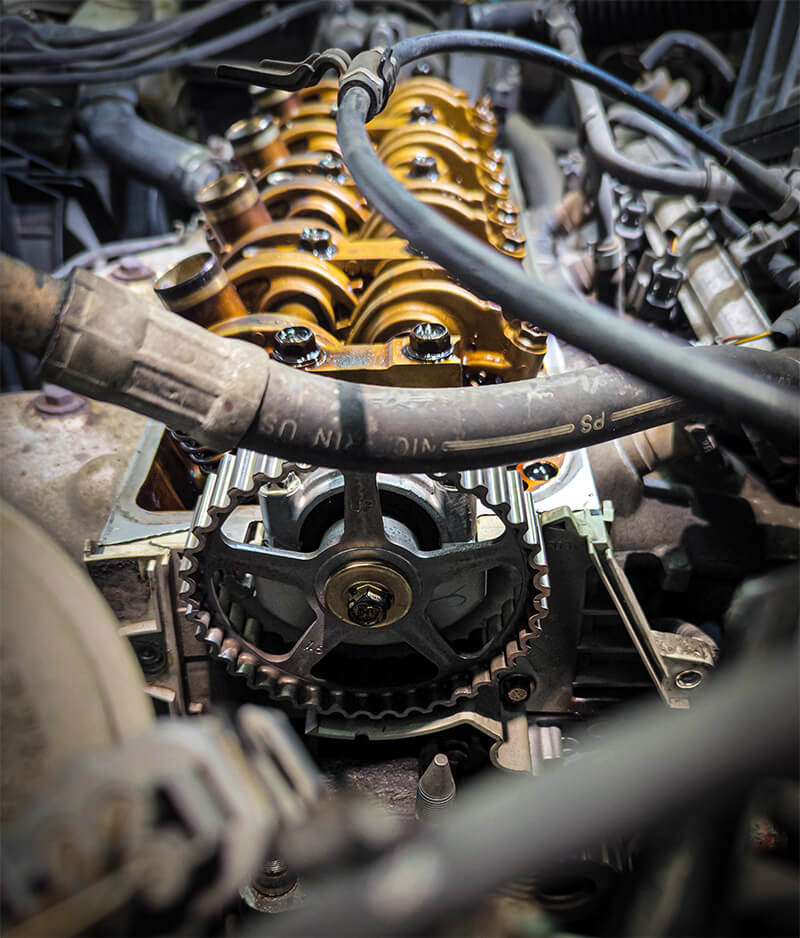

Recently a friend of mine, a heavy-duty truck mechanic, asked if I’d help him replace the timing belt on his car. He’s an experienced wrench but this job left him wanting guidance, knowing the high stakes if something went amiss.

I agreed, of course, and it got me thinking of my own fears the first time I attacked a t-belt. What if I get it wrong? What if I lunch a motor? I knew good and well I needed to be able to do timing belts as a mechanic, so I forged ahead and got the job done. Over the years I learned two things that aren’t often communicated to budding mechanics that would have allayed my fears.

There are only two things you are likely to do wrong. Neither one of them will take out an engine with even the most basic of precautions.

The easiest possible misstep you can make is being “180° out” on the crankshaft.

What that means: The crank spins twice for every revolution of the cam on every conventional four-stroke engine ever made. Top Dead Center (TDC) of the piston occurs at two potential places in the engine’s four strokes. You’ve got your cylinder being timed at the transition between the exhaust and intake strokes, not compression and power, the usual spot for timing.

So if you can line up the timing marks on the cam(s), you are certainly going to have that/those in the right spot. The crank is the only thing you need to worry about—and your odds are 50/50 of getting it right.

Why you shouldn’t worry: If you leave the plugs out and remember to roll the engine over gently by hand after you put the new belt on, you’ll feel interference between a piston and valve that could indicate you are 180° out. Go slowly; I imagine the only thing worse than bending all of a customer’s valves with a timing job gone awry is bending a few with a ratchet!

The only other way a timing belt job can go sideways for the uninitiated is by way of unclear marks.

What that means: Sometimes it seems as though all the timing marks on the spinnin’ pieces don’t want to line up with their corresponding marks on the stationary pieces. Result? When you go to put the new timing belt in place, you appear to be in between teeth on the belt. This can occur due to overshooting the timing marks, sloppy marks from the factory, or not-so-careful alignment before removing the old belt.

Quick aside here: I’ve run into all three situations. Overshooting the timing mark and attempting to back up is usually not a great idea. If you missed the timing mark, keep rotating the engine by hand in the direction it spins when it’s running and come back to it that way. It’s not faster to go “around the horn,” but it is definitely more accurate. Sloppy marks aren’t very common on modern machinery, though I have seen really primitive marks on older and non-automotive engines. And not-so-careful alignment? Well, you know who to blame for that.

Why you shouldn’t worry: If you’re off a tooth, you’re almost certainly not going to grenade the engine. In fact, most systems will forgive an error of two or even three teeth.

So what’s the thing to do? Same as the last. Roll the engine through a few times and see if you can’t get the marks to look a little better once everything is assembled. Get another set of eyes, bright lights, and straightedges; all can help with marks that seem a little unclear. If all else fails, you can mark the old belt and pulleys with a reference point at each. Count the teeth between each, and you can’t screw up.

Now, you are going to suffer consequences if you missed a tooth. You’ll likely throw a check engine light. Maybe that’ll happen at idle, maybe not. Unless the car is ancient, the light will definitely illuminate after the car is warmed up and running down the road at speed. It’s going to shake like a cammed-up muscle car, but it sure as heck won’t perform like one: that set of wheels will exhibit dramatically reduced power.

You’re going to have to redo the job, of course, but the engine will live to fight another day. Given the limited access in many vehicles, yes, that’s a bear, but you’ll be faster the second time around having just done it and having all the correct tools out. It stinks, but I’ve been there before. It happens. You learn, you lick your wounds, and you move on in your career, a little better than you were before it happened.

So don’t get nervous about swappin’ out timing belts. You got this.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.