“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

Dorman makes an item to join wires, the parallel connector, that is both helpful and widely misunderstood. If one reads reviews of these, they’re often rather negative. More than a cursory examination yields the issue, however: these are often purchased mistakenly by people who think they’re just poor butt connectors.

The reality is that the PC is a different animal than a BC, and while uses are limited, the parallel connector is exceptionally good at a few things.

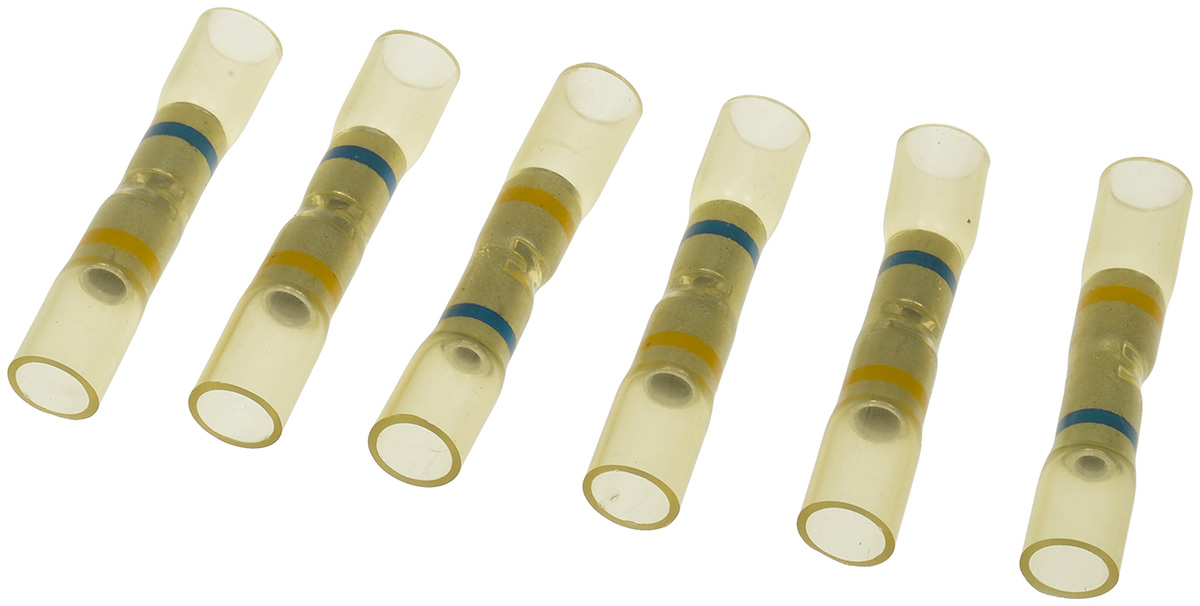

The butt connector is just what its name implies: a crimped connection whereby two wire ends are butted against one another. The connector is a metal sleeve with a tab that acts as a stop between the two sections. Wire is inserted until it butts up against the tab (and the other wire) and then crimped.

Use it: whenever you need to connect two stranded wires that don’t need to be disconnected in the future. You probably already knew this, so let’s move to the less-famous co-star of this article.

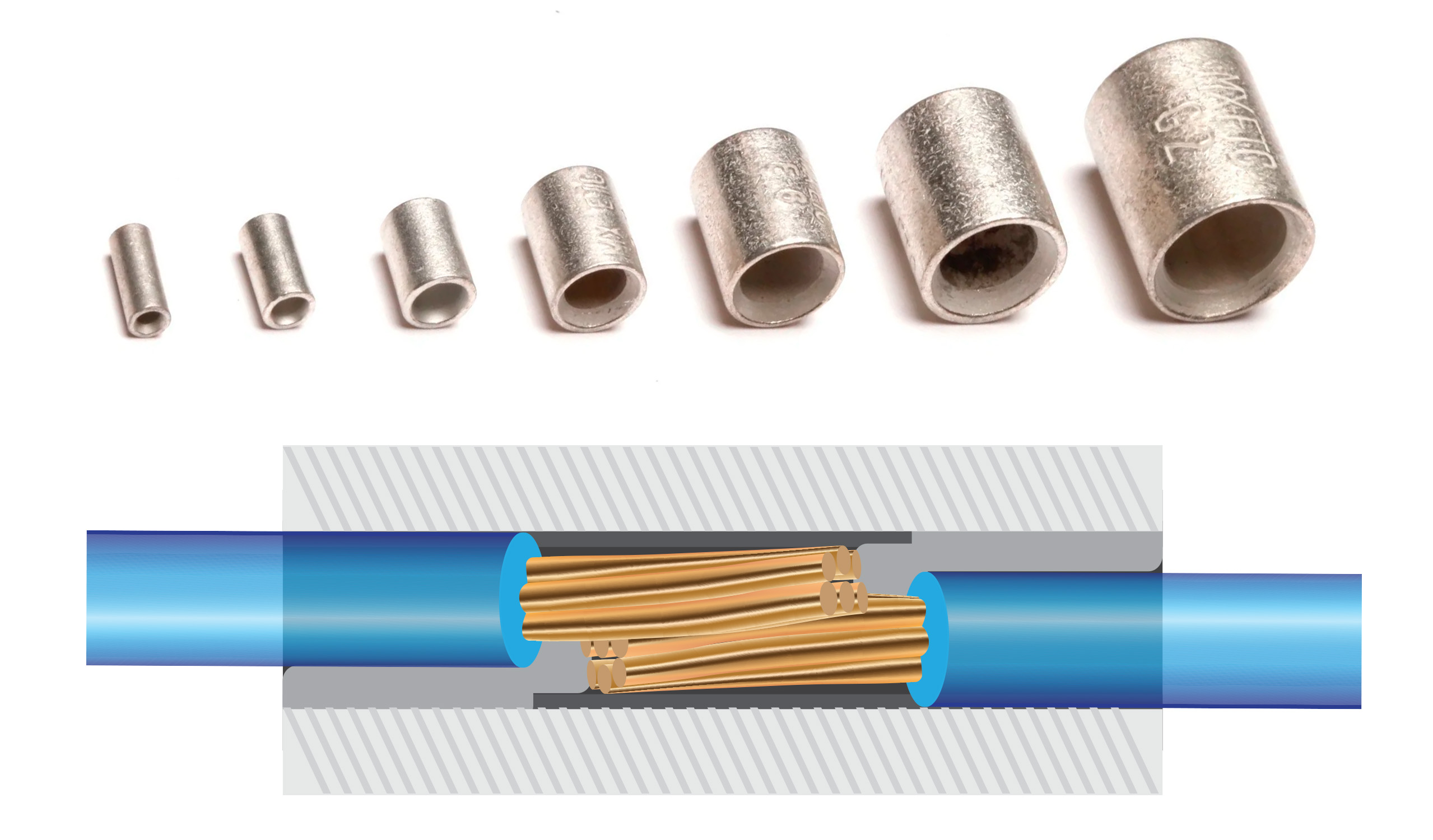

The parallel connector is little more than an aluminum cylinder. It is shorter than the butt connector, and there is no internal stop inside the tube. When using this connector, the wires are laid parallel with one another and crimped.

Use it: when connecting solid and stranded wire. You can’t crimp solid wire at all; think of the wire nuts you would use in home wiring. Wire nuts often take up too much room and are difficult to seal from the elements and they’re hard to install on stranded wire since it wants to do what stranded wire does: be flexible. (Seriously, don’t use wire nuts on a car, please.)

And solder is often inappropriate for joining stranded wire to stranded wire; in the automotive world you’ll usually only see wire soldered to a surface, like a printed circuit board. The most obvious example I can think of is pictured below: wiring a capacitor.

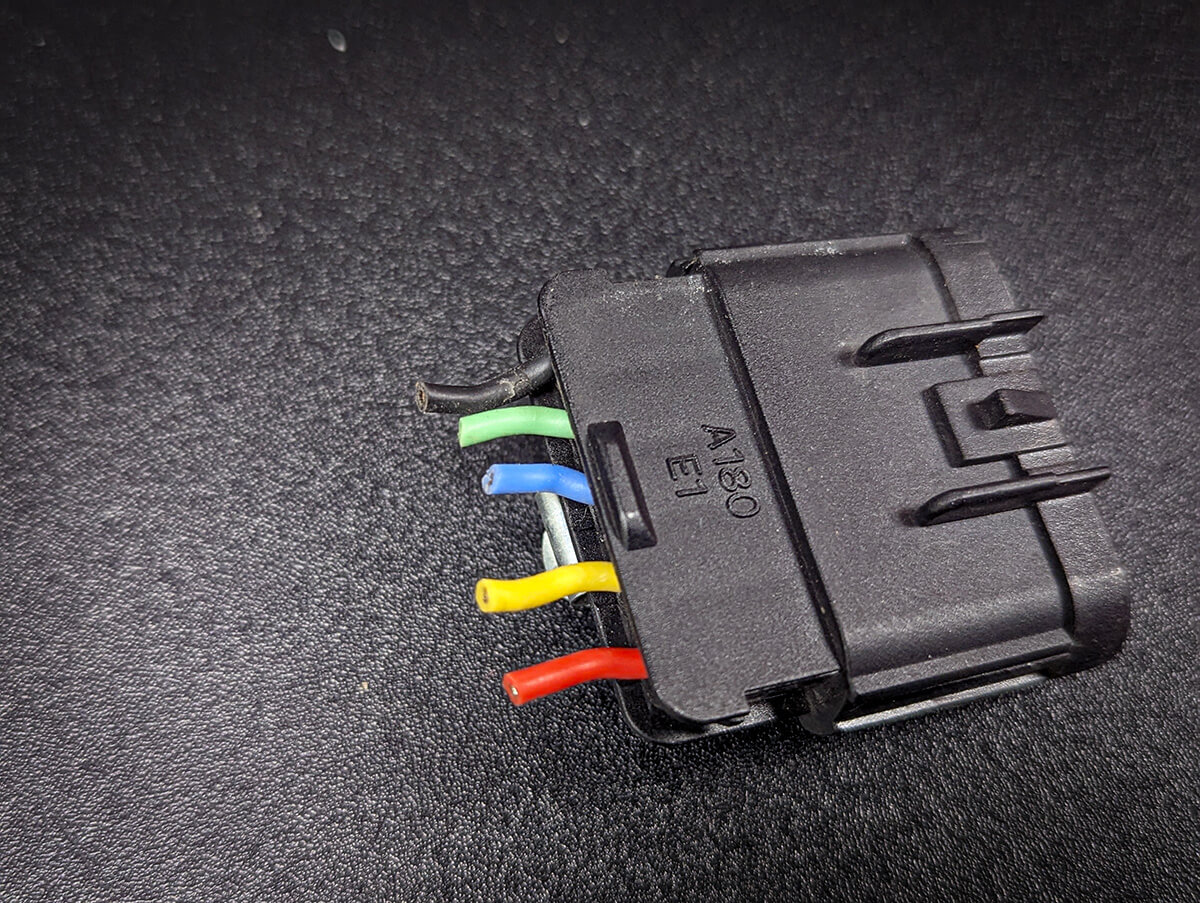

If you had to repair one (or all) of the wires on this harness, the extra length of a butt connector could make the repaired wire unable to traverse a bend unbroken wire could previously. Photo: Lemmy

Use it: when joining two stranded wires of different gauges. Sure, you can buy fancy step-up or step-down connectors. (We’d love to sell you some!) But if the jump in gauge is larger than one step, you can get a much better connection with a parallel connector sized to fit correctly.

Use it: when you don’t have a lot of room or are concerned about strain at a joint. If you are stuck making a repair on a harness connector that needs to be replaced, using parallel connectors can help you remove some of the weight and bulk on the back side of a plug. This isn’t usually the “correctest” solution, but it can be a viable option when repairing something exotic or hard to obtain, and it’s often a way better choice than trying to force a butted connection into a tighter bend than it should see.

Use it: when you need to save time. Car stereo aficionados were just nodding their heads when I mentioned wiring capacitors. But a sub-species of the PC holds a special place in the hearts of most every thump installation expert I know: the crimp cap. If you’re joining a ton of wires, parallel connectors like the crimp cap literally save you half of the work—you make one crimp per connector, not two (like you would with a BC).

Anyone who has even a modicum of respect for vehicle wiring will usually select a harness adapter for stereo installation so as to not hack apart a factory harness. That same person can also tell you what a pain it is to connect so many wires between the stereo harness and the adapter harness, which is why crimp caps are the gold standard when performing this work.

There’s more than one way to join wires—and more than one product to make it easy.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.