Patching a punctured tire is a common job, but are you up to date on the latest guidance for safe plug locations?

In the world of commercial aircraft, parts are almost always replaced before the end of their expected service lives. Rather obviously, a plane that stops flying mid-flight presents some pretty serious hazards to the health and safety of the passengers and people on the ground beneath them. Because of this, aircraft are scrutinized heavily, and parts are replaced well before they’re ready to give up the ghost.

This systematic approach to vehicle maintenance can be applied to cars, you know. It can be a boon, especially for well-heeled customers who would be willing to pony up a few extra dollars to sidestep the downstream costs of an unplanned repair leaving them without a car, or worse, stranded in one.

And the way to sidestep this is to write up an estimate with not just things that have broken, and preventive maintenance as suggested by the vehicle manufacturer, but by applying a little forethought to what’s likely to break next and including those bits, too. Let me give you a couple examples.

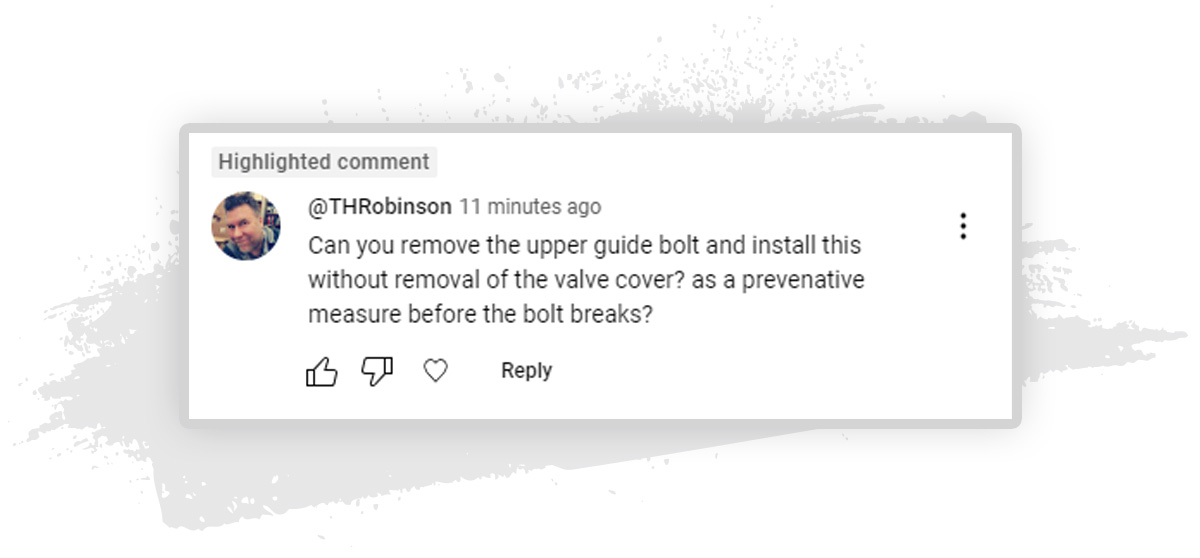

Someone left the following comment on a video for our 917-954 recently.

My, what a proactive motorist!

This part is a cam chain guide bolt repair kit for GM Ecotec engines. (If you’re unfamiliar with the problem, here’s a little explainer on how this thing works. It’s pretty neat. No, I’m not trying to sell you one. Knowing how it works is important to the crux of the article.)

I thought it was an interesting comment for a couple reasons. First, one of my junk commuter vehicles has one of these engines, and I swapped one of these in when I got it. For the fifteen bucks it costs to just do it and forget about it being a problem, it was an easy decision. (For reference, for a paying customer, this whole job probably would land around a hundred bucks—it’s an easy install.) The other nice part about this particular part is that it saves one from having to fish out the bolt that breaks. It might end up in the oil pan—if you get lucky. Or maybe it caroms around the timing chain cavity for a bit and ends up in pieces. Or maybe it breaks and then wipes out the tensioner.

So my answer to the forward-thinking YouTube inquirer was yes, absolutely you can replace this thing as a preemptive repair. And the money one spends on the part and even labor to install it is most certainly going to be offset by the money the customer will not spend on the tow truck, the hour of diagnostic time, the loss of a vehicle, and the potential replacement of timing chains and guides.

Another item that comes to mind is the Jeep OPDA (oil pump drive assembly; it’s basically a cam synchronizer) that existed in the final form of the venerable straight-six. Effectively a huge cam sensor, this thing basically plugged into the block where a distributor used to go many moons ago. Due to a crummy design that starves the unit of lubrication, the original part on these had a spectacularly high failure rate. The 689-201 we sell fixes that problem. (Again, not a sales pitch. You just need a good description of the problem.)

I recommended these things left and right to people who had the narrow run of Wranglers they fit, and installed quite a few of them, too. Some were sold after the original failed and made a racket, but most I recommended prematurely. Left unchecked, a damaged unit would often wipe out the corresponding cam gear, which sends the cost of the repair skyrocketing. Let’s also not forget about the crank/no-start condition or intermittent P0016 codes that might be generated by this part. And of course, there’s the wrecker that transports this now-dead vehicle to your facility; that’s not free. Customers will wind up funding these additional, related issues if the problem is not rectified.

Now I’ve mentioned all this because situations like these helped me write better estimates. Bigger, yes, but also more helpful. Look, repair always sells; that’s why they call it an RO. The car comes in with a problem and the customer usually has already decided to spend at least something before arriving at your counter.

Preventative maintenance is harder to sell since there is often no acute problem, but customers who have been through the wringer will happily pay to avoid costly and inconvenient unplanned repairs. (You know who these customers are. You see them all the time, and they happily authorize anything you recommend. They are the lifeblood of our businesses; the steady clients who keep our families eating.)

But what about preventative repair? It’s practically an untapped market, but it’s positively ripe to mine for additional dollars for your till. And it’s a perfect recommendation for three types of customers:

All of these customers can easily understand the value of repairing the problem before it actually becomes a problem. And in the case of the last two customers, how better could you possibly demonstrate your automotive expertise? “Hey, I’ve seen this movie and I can tell you how it ends. Let’s short circuit the tow truck driver and the huge bill I’ll hand you to clean up this mess later and just go with a planned, known cost right now or in the very near future.” What customer won’t feel like you’ve got his back after hearing that?

So your homework is to become sensitive to repair patterns. We all know a few of the common offenders—Subarus frying CV boots, Fords spitting spark plugs, and Nissan CVT failures come to mind. Spend some time on the not-yet-dead automotive forums and social media that concentrates on repair. See what other shops are seeing.

Keep an eye on common failures on specific vehicle platforms and let your customers know what they are (and more importantly, what you can do to prevent them from succumbing to them). Even if the end result is a vehicle owner who wants to go home and do a little research, you can bet the reciprocity effect will kick in. Mark my words—if the customer does indeed decide to pay for the suggested repair, your shop will get the business.

Don’t turn down the opportunity to talk vehicles with a customer—even some idle, innocuous chitchat about problems common to this vehicle or that one make might just be you soft-selling your customer on a repair. Don’t be surprised if your customers—and your techs and your boss—thank you.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.