“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

DTCs (Diagnostic Trouble Codes) P0420 and P0430 are generic industry codes and part of the OBD-II standards. The descriptor labels the code(s) “Catalytic Converter Efficiency Below Threshold – Bank 1 (or 2)”. And the number one part sold to repair this problem is a replacement catalytic converter. But, in many cases, this fails to correct the problem, and the Check Engine light soon returns. So, what causes these codes, and how do you successfully repair the vehicle?

The key to understanding these codes is the phrase “efficiency below threshold.” The ECM (Engine Control Module) sets these codes when it determines that the catalytic converter is not working as expected. The converter’s role, if you did not know, is to clean up the exhaust gases leaving the engine to reduce exhaust emissions. The ECM keeps an eye on its function by monitoring the state of the gases going into the converter and leaving it after conversion.

Either a conventional zirconium oxygen sensor or, on later models, an AFS (Air Fuel Sensor), also referred to as a wide band oxygen sensor, is used to inform the ECM of the state of the gases entering the converter. They are located upstream of the cat, and the signals sent to the ECM from these sensors should switch from lean to rich continuously as the ECM maintains the air/fuel ratio going to the engine.

The sensor located on the other side of the cat is referred to as the downstream sensor. It is a zirconium sensor, but manufacturers, in the interest of better efficiency and reduced emissions, are starting to use AFS sensors here as well. After the catalytic converter has processed the exhaust, the gases leaving should be cleaned up, and the downstream sensor will switch very little, if at all.

If the converter is unable to do its job, the gases leaving the converter will be increasingly like the gases that went in, and the downstream sensor will start to mirror the signal from the front sensor. This comparison between the front and rear sensor is the switch ratio and is the most common strategy the OEs use to evaluate the cat. When the upstream is switching but the rear is stable, that is a switch ratio of 0:1. When they get to be mirror images of each other, that is a switch ratio of 1:1. On most cars, the failure limit is a threshold of 0.7:1.

All the code(s) mean is that the converter is no longer able to do its job. While the catalytic converter may be bad and require replacement, it is not the only possible cause for the codes. When tackling these DTCs, the first step is to understand how converters fail.

A common cause of converter failure is overheating, leading to damage to the converter substrate. Overheating, though, is typically a result of problems in the feed gases entering the converter. These feed gases must be maintained in a very narrow lambda range for the converter to work most efficiently. If not, the converter will overheat.

Another common cause is poisoning of the converter. This occurs when the substrate becomes covered with a foreign substance—usually oil or coolant. If the substrate is coated, active conversion cannot take place.

Physical damage is also a cause of converter failure. Damage to the converter housing, cracks in the exhaust system allowing air into the converter, and broken welds are all examples of physical damage.

Begin by performing a visual inspection of the exhaust system. Any physical damage to the converter will most certainly require replacement.

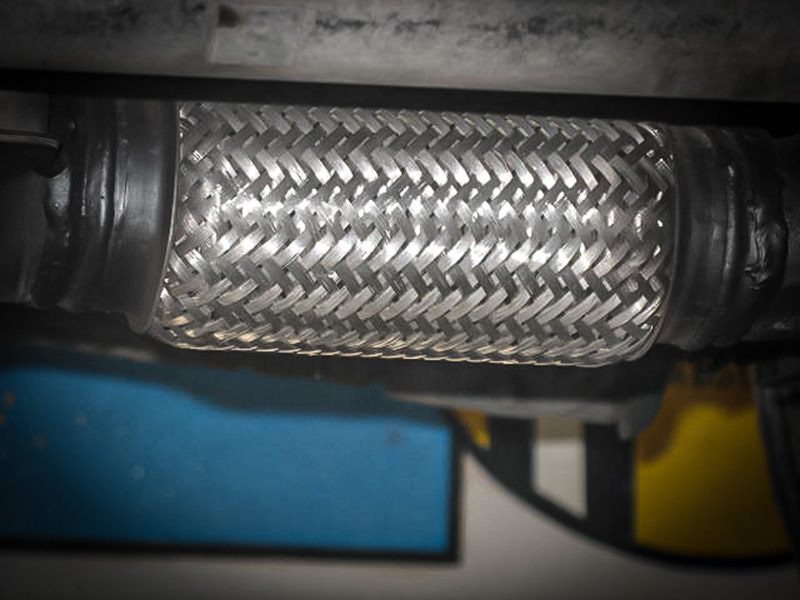

Flex pipe is a common source of exhaust leaks, letting in air that can throw off the oxygen sensors and cause a false code.

Look closely for any signs of exhaust system leaks, especially on the exhaust manifold, any flex pipe used, and around the oxygen sensor bungs. A shop vacuum can be used to pressurize the exhaust system. Simply swap the hose from the intake to the exhaust of the vacuum and insert it into the tailpipe, sealing it with duct tape. Turn the vacuum on and spray a mix of dishwashing liquid and water around any possible source of leakage.

Next, use a soft rubber mallet and lightly tap on the side of the converter. If you can hear pieces of the substrate bouncing around, the cat will need to be replaced.

The next step is to see if any conversion is taking place. This can be done with an IR temperature gun or, better yet, a thermal imager.

Use an IR temperature gun or thermal imager (shown) to see if conversion is taking place.

Bring the vehicle up to full operating temperature. Using the thermal imager, measure the temperature at the weld ring on the inlet side of the converter. Next, measure the temperature of the weld ring on the outlet side of the converter.

The conversion process creates heat. If the outlet is 20 degrees or more hotter than the inlet, odds are good that some conversion is taking place. A word of caution here—this test should only be used to see if the cat is working and not to use as a pass/fail test. The cat must reach a certain temperature before the conversion process can take place.

The P0420/P0430 codes, accompanied by a loss of power complaint, may indicate a melted substrate that is causing an exhaust restriction. This can be verified in several ways. Testing the engine’s volumetric efficiency (that is, the ability of the engine to “breathe”), using the thermal imager, and removing the converter and attempting to look through it are all effective methods. I want to stress that looking at just the front or rear of the converter is not conclusive. Melted substrate occurs first near the center of the converter.

Old school test of exhaust back pressure.

If the substrate has melted, it indicates that the heat generated in the converter has been excessive. It is imperative that you identify and correct the cause of the failure, or any new converter you install will have a noticeably short life span.

There are additional ways to inspect the operation of the converter.

If the vehicle uses conventional oxygen sensors, you can compare the switching activity using a scan tool in graph mode or, for even greater accuracy, a DSO (digital storage oscilloscope). If the front sensor is a wideband sensor, you cannot use its voltage PID (Parameter Identifier). Instead, look for a data PID that displays the sensor’s current value. Remember, this is what the ECM is looking at to determine how the cat is performing.

Mode $06 is also a good place to look for information. Review the test results for the Catalyst Monitor, especially anything that indicates switch rate.

Specifically, we are looking at is the test result compared to the minimum and or maximum test values allowed. Think of those values as goal posts. The closer the test result is to either value, the closer the test is to failing.

Do not forget to check for any related TSBs (Technical Service Bulletins). Many times, all that is needed is a reflash to turn the Check Engine light off. This is a good possibility if your earlier observations lead you to believe that the cat is working even though the ECM says it is not.

Cleaning the converter using a slow drip fuel induction cleaner added through a central vacuum port may bring the converter back to life.

Note the current Mode $06 test results before attempting to clean the converter. Then compare the new test results after the cleaning. If you note an improvement, then the DTCs may have been caused by converter poisoning.

While the cleaning may restore the converter’s efficiency, it will not correct the cause of the poisoning. But then again, if the cleaning gets another 40,000 or more miles out of the converter, I am sure your customer will appreciate not having to spend the money on a major engine repair for an oil or coolant issue that is not affecting the vehicle’s driveability.

A professional technician does not repair symptoms of a customer concern, but the cause of the problem. Dealing with these codes is a splendid example of how simply replacing a part because it was called out in the DTC descriptor could lead to a dissatisfied customer and the replacement of an often extremely expensive part. Do not be that guy—take advantage of the training opportunities the Dorman Training Center has to offer.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.